In today’s fast-paced business environment, companies are constantly searching for innovative methods to streamline their product development processes. One of the most transformative technologies emerging in recent years is 3D printing. This cutting-edge technology is not only reshaping prototyping but is also offering a plethora of benefits for businesses looking to cut costs and improve efficiency.

Understanding 3D Printing in Prototyping

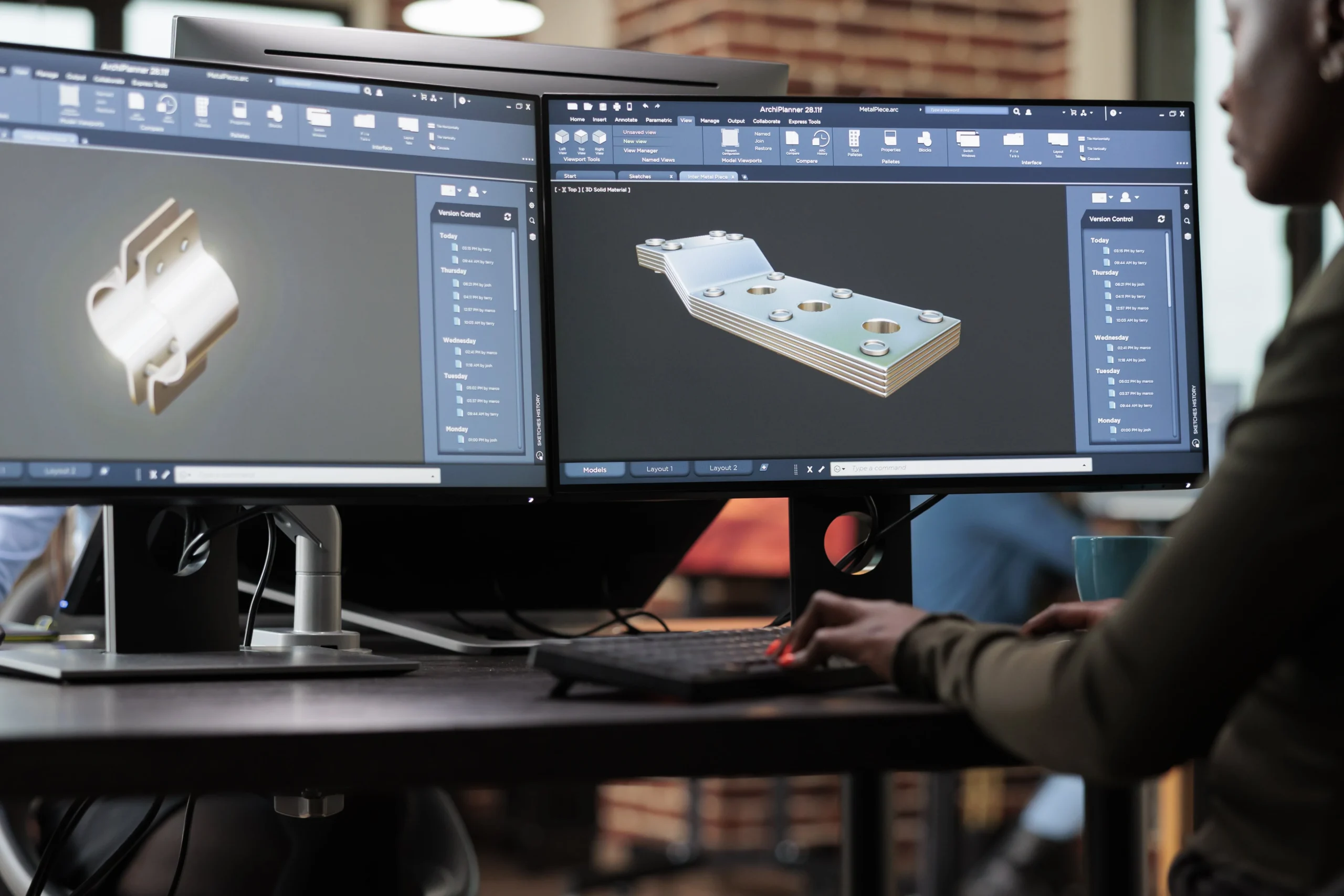

3D printing, also known as additive manufacturing, involves creating three-dimensional objects from a digital file. This process allows designers to build prototypes layer by layer using various materials, including plastics, metals, and ceramics. As a result, businesses can produce functional prototypes more rapidly and at a lower cost compared to traditional manufacturing methods.

Benefits of 3D Printing for Prototyping

-

Cost Efficiency

One of the most significant advantages of 3D printing is its cost-effectiveness. Traditional prototyping methods often require expensive tooling and molds, which can lead to high upfront costs. In contrast, 3D printing eliminates the need for such investments, allowing companies to create prototypes without incurring excessive expenses. This is particularly beneficial for startups and small businesses, as they can allocate resources more effectively.

-

Faster Turnaround Times

Speed is crucial in product development. With 3D printing, businesses can significantly reduce the time it takes to move from concept to prototype. Traditional methods can take weeks or even months, while 3D printing can produce prototypes in a matter of hours or days. This rapid turnaround allows companies to iterate designs quickly, gather feedback, and make necessary adjustments without delays.

-

Increased Design Flexibility

3D printing provides unparalleled design flexibility. Designers can create complex geometries and intricate details that would be difficult or impossible to achieve with traditional methods. This capability not only enhances creativity but also allows businesses to explore innovative solutions that can lead to better products. Additionally, modifications to the design can be made easily, further streamlining the prototyping process.

-

Reduced Material Waste

Sustainability is becoming increasingly important in product development. 3D printing is inherently more sustainable than traditional manufacturing processes, as it generates significantly less waste. Since 3D printing builds objects layer by layer, materials are only used where needed, minimizing excess material. This not only reduces costs but also contributes to a more sustainable manufacturing process.

-

Enhanced Collaboration

With 3D printing, teams can create prototypes that can be easily shared and reviewed. This collaborative approach fosters better communication among team members, clients, and stakeholders. By providing tangible models, businesses can facilitate discussions around design choices and functionality, ultimately leading to more informed decision-making.

Real-World Applications of 3D Printing in Prototyping

Several industries have already begun to harness the power of 3D printing for prototyping. For instance, the automotive industry uses 3D-printed prototypes to test new designs and functionalities before full-scale production. Similarly, the healthcare sector utilizes 3D printing to create patient-specific implants and prosthetics, significantly enhancing the customization and effectiveness of medical devices.

Examples of Companies Leveraging 3D Printing

- Nike has implemented 3D printing in its design process to create custom-fit shoes, ensuring better performance and comfort for athletes.

- Boeing utilizes 3D printing for producing lightweight components, resulting in reduced fuel consumption for their aircraft.

- GE has integrated 3D printing into its jet engine manufacturing process, enabling faster production and enhanced performance of engine components.

Conclusion

In conclusion, 3D printing is revolutionizing prototyping in product development. With its cost efficiency, faster turnaround times, increased design flexibility, reduced material waste, and enhanced collaboration, businesses can significantly improve their product development processes. As technology continues to evolve, companies that embrace 3D printing will be better positioned to innovate and succeed in today’s competitive landscape.

For more information on how 3D printing can transform your business, check out this article from McKinsey and this guide from Forbes.